Course Structure

The B.Tech program at Gulzar Group of Institutions offers a comprehensive curriculum spanning eight semesters.

Engineering Physics introduces fundamental principles of physics and their applications in engineering, providing students with a solid understanding of core concepts essential for their academic and professional pursuits.

Engineering Mathematics is a foundational course that provides students with essential mathematical concepts and techniques relevant to engineering applications. Topics covered include calculus, differential equations, linear algebra, and more.

Basic Electrical Engineering introduces fundamental concepts of electricity and circuits, including Ohm’s Law, Kirchhoff’s Laws, circuit analysis techniques, and components like resistors, capacitors, and inductors.

Engineering Graphics & Design introduces students to technical drawing principles, visualization techniques, and drafting tools. Through hands-on practice and CAD software, students learn to create detailed engineering drawings and designs.

Chemistry explores the properties, composition, and behavior of matter. It covers fundamental concepts like chemical bonding, stoichiometry, and states of matter, providing the groundwork for advanced chemical studies.

Engineering Mathematics is a foundational course that provides students with essential mathematical concepts and techniques relevant to engineering applications. Topics covered include calculus, differential equations, linear algebra, and more.

Programming for Problem Solving introduces students to fundamental coding principles and problem-solving techniques. Through practical exercises, students develop analytical skills and learn to implement solutions using programming languages.

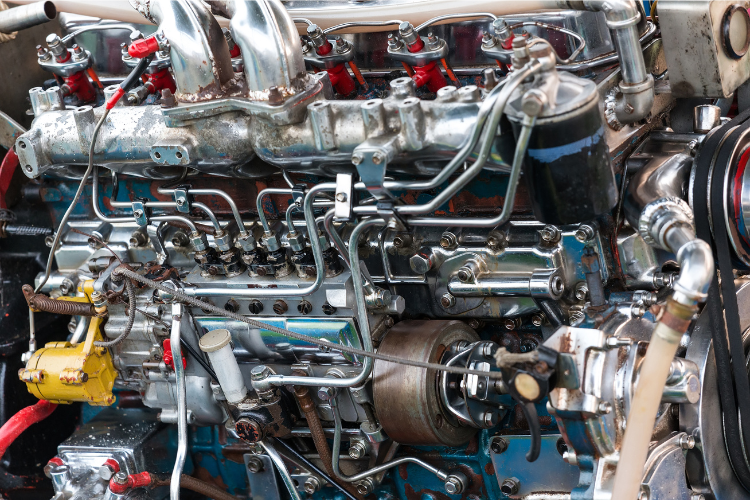

Workshop/Manufacturing Practices immerses students in practical experiences, teaching essential skills in manufacturing processes, machinery operation, and safety protocols. Through hands-on workshops, students gain valuable insights into real-world manufacturing environments.

English focuses on enhancing students’ communication skills, including reading, writing, speaking, and listening. Through interactive sessions, students develop proficiency in English language usage, essential for effective communication in academic and professional contexts.

Fluid Mechanics explores the behavior of fluids under different conditions, covering topics like fluid dynamics, flow measurement, and applications in engineering systems. It equips students with essential skills for fluid-related problem-solving.

Theory of Machine” delves into the principles governing the motion and forces of mechanical systems. Topics include kinematics, dynamics, and analysis of mechanisms, preparing students for designing and analyzing complex machines.

Strength of Materials explores the behavior of materials under various loads and stresses. Students learn about concepts like elasticity, plasticity, and fracture mechanics, vital for designing safe and durable mechanical components and structures

Basic Thermodynamics covers fundamental principles of energy transfer, laws of thermodynamics, heat transfer mechanisms, and their engineering applications, providing a foundational understanding of energy processes and system performance.

Basic Electronics Engineering covers semiconductor devices, electronic circuits, amplifiers, digital electronics, and integrated circuits. It provides foundational knowledge essential for understanding electronic systems and their applications in engineering.

Machine Drawing teaches students the fundamentals of creating detailed technical drawings for machine components and assemblies, essential for effective communication in engineering and manufacturing.

Fluid Machines explores the principles and applications of devices that manipulate fluid flow, such as pumps, turbines, and compressors, vital in various industries including energy generation, transportation, and manufacturing.

Applied Thermodynamics explores the practical application of thermodynamic principles in engineering systems, including power plants and HVAC systems, essential for optimizing energy conversion processes in diverse industries.

Strength of Materials explores the behavior of materials under various loads and stresses. Students learn about concepts like elasticity, plasticity, and fracture mechanics, vital for designing safe and durable mechanical components and structures.

Materials Engineering is a crucial discipline that involves the study and application of materials in engineering. It encompasses material properties, selection, processing, and performance evaluation for diverse industrial applications, ensuring optimal functionality and durability.

Theory of Machine delves into the principles governing the motion and forces of mechanical systems. Topics include kinematics, dynamics, and analysis of mechanisms, preparing students for designing and analyzing complex machines.

Heat Transfer involves the exchange of thermal energy between objects or systems due to temperature differences. It’s vital in engineering for designing efficient cooling/heating systems and managing thermal processes in various applications.

Design of Machine involves creating mechanical systems to fulfill specific functions efficiently. It includes conceptualization, analysis, and implementation of components and mechanisms for desired performance and reliability in various industries.

Manufacturing Processes explores various techniques like casting, machining, and welding, vital for converting raw materials into finished products. This subject is crucial for understanding industrial production methods and ensuring product quality.

Management and Engineering Economics integrates principles of management with economic analysis to enhance decision-making in engineering projects. It covers cost management, project evaluation, and economic feasibility studies for engineering solutions.

Refrigeration and Air Conditioning in Mechanical Engineering covers principles, systems, and applications of cooling and heating technology, including air conditioning, refrigeration cycles, and HVAC systems for various industrial and residential purposes.

Mechanical Measurement and Metrology involve the study and application of techniques for accurate measurement and assessment of mechanical components, ensuring precision and quality in engineering processes and products.

Automobile Engineering focuses on the design, manufacturing, and maintenance of automotive vehicles, covering areas such as engine design, vehicle dynamics, safety systems, and alternative fuel technologies.

Introduction to Industrial Management covers key principles in organizational structure, production planning, quality management, and supply chain logistics, providing essential knowledge for effective management within industrial settings.

Mechatronics System integrates principles of mechanical engineering, electronics, computer science, and control engineering to design and develop smart systems, robots, and automated processes for various industrial applications.

Mechanical vibration is the study of oscillatory motions of mechanical systems and structures. It involves analyzing vibrations, their causes, effects, and methods for controlling or mitigating them to ensure optimal performance and safety.

Artificial intelligence (AI) simulates human intelligence in machines, enabling them to think, learn, and problem-solve like humans. It finds applications in diverse sectors such as healthcare, finance, and transportation.

Computer-aided design (CAD) involves using computer software to create, modify, analyze, or optimize designs for various engineering projects. It enhances productivity and accuracy in the design process across industries.

Automation in manufacturing refers to the integration of machinery, robotics, and computer systems to optimize production processes, enhance efficiency, and improve quality in manufacturing operations.

Product Design and Development is a process that involves conceptualizing, designing, and bringing a product to market. It encompasses ideation, prototyping, testing, and refining to meet customer needs and market demands.

Industrial & Software Training encompasses programs aimed at providing individuals with essential skills for industry work and proficiency in relevant software tools, offering hands-on experience and practical knowledge.